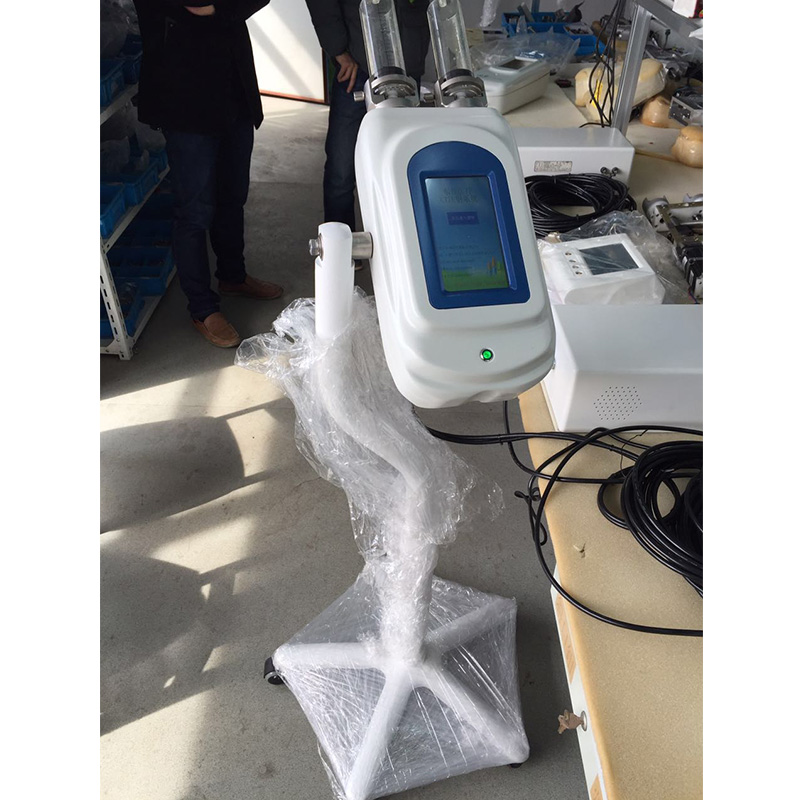

Vacuum Forming Plastic Shell for Medical Equipment – Precision, Durability, and Hygiene

Medical devices require protective enclosures that ensure safety, hygiene, and durability. This vacuum forming plastic shell is designed specifically for medical applications, offering superior protection, a lightweight structure, and long-lasting performance. Crafted using advanced vacuum forming shell technology, this vacuum plastic shell ensures a seamless fit, making it the perfect medical equipment shell for hospitals, laboratories, and healthcare facilities.

1. High-Quality Material for Maximum Protection

A reliable vacuum forming plastic shell is essential for protecting delicate medical instruments. This vacuum forming shell is made from premium-grade plastic, offering:

Impact Resistance – Shields medical devices from damage due to accidental impacts.

Lightweight Yet Sturdy Build – Ensures easy handling without compromising durability.

Corrosion and Chemical Resistance – Withstands exposure to disinfectants and cleaning agents.

The high durability of this vacuum plastic shell makes it an excellent choice for a medical equipment shell, ensuring long-term performance in medical environments.

2. Precision Engineering with Vacuum Forming Technology

Using cutting-edge vacuum forming plastic technology, this vacuum forming shell guarantees a flawless design that meets medical industry standards. Key benefits include:

Smooth, Seamless Surface – Prevents bacterial buildup and facilitates easy cleaning.

Perfect Custom Fit – Molds precisely to the shape of medical devices.

Enhanced Strength and Stability – Maintains structural integrity under stress.

This vacuum plastic shell is the preferred choice for manufacturers looking for a medical equipment shell with high precision and quality.

3. Hygienic and Sterilization-Friendly Design

Medical facilities require materials that comply with strict hygiene standards. This vacuum forming plastic shell offers:

Non-Porous Surface – Prevents the accumulation of bacteria and other contaminants.

Compatibility with Medical-Grade Disinfectants – Allows for easy cleaning and sterilization.

Heat and Chemical Resistance – Maintains integrity even with frequent sanitation.

As a medical equipment shell, this vacuum plastic shell ensures the highest levels of hygiene, making it an essential component in healthcare settings.

4. Wide Applications Across Medical Industries

This vacuum forming shell is designed for a variety of medical applications, including:

Diagnostic Devices – Perfect for enclosing MRI, CT scan, and ultrasound machine components.

Patient Monitoring Systems – Protects vital sign monitors and other electronic devices.

Surgical and Laboratory Equipment – Provides protective housing for essential medical tools.

As a vacuum forming plastic product, this vacuum plastic shell ensures the safety and longevity of medical devices while maintaining easy access for healthcare professionals.

5. Cost-Effective and Eco-Friendly Manufacturing

Beyond functionality, this vacuum forming shell is also an environmentally friendly and budget-conscious choice. Key advantages include:

Recyclable Materials – Contributes to sustainable manufacturing practices.

Energy-Efficient Production Process – Uses less energy compared to injection molding.

Affordable Without Compromising Quality – Reduces production costs while maintaining superior performance.

Choosing this vacuum plastic shell for your medical equipment shell needs means selecting a cost-effective, durable, and eco-conscious solution.

Why Choose This Vacuum Forming Plastic Shell?

✅ Durable and Impact-Resistant – Offers long-lasting protection for medical equipment.

✅ Hygienic and Easy to Maintain – Complies with sterilization requirements.

✅ Lightweight Yet Strong – Ensures durability without adding excessive weight.

✅ Eco-Friendly and Cost-Effective – Reduces environmental impact while saving costs.

✅ Smooth, Seamless Finish – Enhances appearance and functionality.

Upgrade your medical devices with this vacuum forming plastic shell. Whether you need a vacuum forming shell for advanced medical equipment or a vacuum plastic shell for lab tools, this medical equipment shell is the ultimate solution.